Ultrasonic Pulse Velocity Test

ULTRASONIC PULSE VELOCITY TEST AS PER IS 516 PART-5 SEC-1 2018

The Ultrasonic Pulse Velocity (UPV) test is a non-destructive method used to assess the quality and integrity of concrete structures. It measures the speed at which an ultrasonic pulse travels through the concrete, revealing information about its uniformity, homogeneity, and the presence of internal defects like cracks.

How it works:

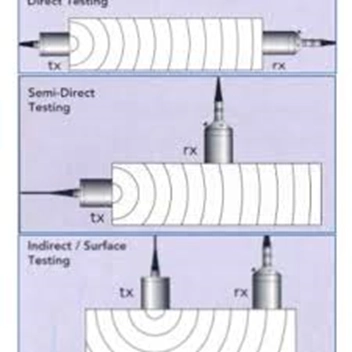

- Transducer Placement: Two transducers are placed on opposite sides of the concrete member being tested (direct transmission) or, in some cases, on the same side (surface probing).

- Pulse Generation: The transmitting transducer generates an ultrasonic pulse that travels through the concrete.

- Pulse Reception: The receiving transducer detects the pulse, and the time taken for it to travel between the transducers is measured.

- Velocity Calculation: The pulse velocity is calculated using the formula: Velocity = Path Length / Travel Time.

Interpreting the results:

- Higher velocities: generally indicate better concrete quality, with less internal flaws, cracks, or voids.

- Lower velocities: may suggest poor concrete quality, such as the presence of cracks, voids, or honeycombing.

- The test can also be used to estimate the dynamic modulus of elasticity of concrete.

Key benefits of UPV testing:

- Non-destructive: The test doesn't damage the concrete structure.

- Quick and reliable: Results are typically obtained quickly, making it an efficient method for quality assessment.

- Can be used to detect a range of defects: Cracks, voids, and other imperfections can be identified.

Factors influencing UPV measurements:

- Concrete quality: Density, uniformity, and homogeneity affect pulse velocity.

- Presence of defects: Cracks and voids slow down the pulse.

- Material properties: Aggregate type and mix proportions can affect pulse velocity.

- Moisture content: Moisture can influence the pulse velocity.